Description

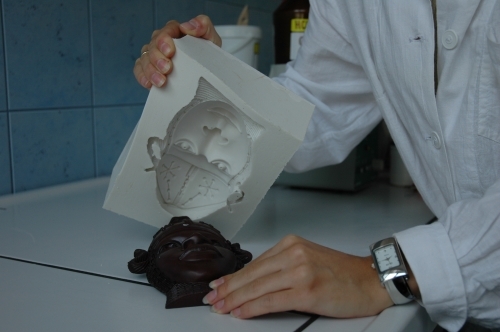

HOW TO MAKE MOULDS

Contents in the courier box: Silicone Rubber RTV, Curing Agent.

Opening of courier box, Silicone Rubber Container & Curing agent Bottle : Open the courier box by keeping the arrow mark upward. Pull the lid upwards then you can open the lid easily. This secure seal has been used to keep your Silicone Rubber leak proof. Before opening the Curing Agent bottle shake it slowly 2-3 times.

Information about Silicone Rubber : The best rubber for general-purpose mold-making is called 2-part liquid Silicone Rubber RTV (Room Temperature Vulcanizing). Which is in your hands now. It’s compatible with most Master pattern materials such as Plastics, Poly Resin, Clay, Wood, Metal, Marble.

Master or Pattern preparation for Mold making and Mold Box : Clean the master or pattern fully, no dirt should be there. Then fix it in your Mold box with some clay or liquid wax. The Mold Box can be made of laminated plyboard or Acrylic Sheet. For smaller masters, you can use disposable paper or plastic containers also.

Very Important::::Sealing of Master or Pattern : If the master is made of some porous material like Wood, Clay, Plaster, Marble, etc. then you have to seal it before pouring Silicone Rubber on it so that Silicone Rubber does not sink into its tiny holes. To seal it you can spray 2-3 coatings of Teflon spray or you can apply Sealing Agent with a brush. If you use Teflon Spray then no need of any other Releasing Agent. If you use the Sealing Agent only then you should apply a Silicone Free Releasing Agent on it again. If you have nothing of the above then apply Vaseline, Silicone Oil Or Mansion Wax Polish, depends on the material of pattern.

Must do a test on a small section to determine if it tends to stick or not. If you are molding something precious, test a small area to check for bad effects- sometimes the release will discolor marble or ruin the finish of a carved wood piece.

Mold Releasing Agent : Generally Silicone Rubber does not need any mould releasing agent but if you are the first time user or your Master has deep curves and deep undercuts then to be on the safer side you can use any Silicone Free releasing agent or any all purpose releasing agent. Just spray 1-2 times on the whole master and inside of the Mold Box where you think the Silicone Rubber can reach. Let it dry for 15-20mintues. If you have nothing of the above then apply Vaseline, Silicone Oil Or Mansion Wax Polish.

Weighing, Measuring and Mixing of Silicone Rubber & Curing Agent / Hardener: PLEASE TEST SILICONE RUBBER WITH A SMALL QUANTITY OF 100 GRAMS BEFORE GOING FOR BIG QUANTITY MIX.

Weigh the required Silicone Rubber in any clean HDPE, PVC container or Disposable Plastic Cup. Then add 1.5% or 2.5% or 3% or 5% or 10% or 50:50 ratio (according to written on curing agent bottle) Curing agent into it and mix both well for 1-2 minutes with any clean rod. Do not forget to scrape and mix from the inner sides of the container because the curing agent has the tendency to stick/adhere to the walls of the container.

Pouring of the Mixture : Now your Master and Silicone Mixture is ready. Start pouring the Silicone Rubber mixture at one corner and keep on pouring at this point and let the silicone rubber flow to the whole master and fill the Mold box. With this, no air will entrap into your Mold.

Demolding : After pouring let it remain as it is for 6 to 24 hours, ( depends on Silicone Rubber You choose and Weather conditions ) then de-mold it slowly. Now your Mold is ready to cast materials into it. After applying any releasing agent, You can cast Poly Resin, Epoxy Resin, PU Resin, Plaster, GRC, Molten Wax and many other composite materials into this Mold.

Reviews

There are no reviews yet.